What is Pipe Relining? Understanding a Modern Solution

What is Pipe Relining? Understanding a Modern Solution

Pipe problems can wreck your entire yard and drain your wallet. Traditional repairs mean digging up driveways or gardens and causing days of chaos. But pipe relining flips the script. Thanks to this trenchless repair method you could have your entire plumbing system restored in just a few hours with no need for landscape destruction and up to 75 percent less disruption compared to excavation . The surprising part? The new relined pipe interior is actually stronger than many brand new pipes.

Table of Contents

Quick Summary

| Takeaway | Explanation |

|---|---|

| Pipe relining minimizes property disruption | The trenchless method avoids extensive excavation, preserving landscapes and existing structures. |

| It significantly reduces repair costs | Homeowners save on landscaping and restoration expenses compared to traditional replacement methods. |

| Durable and long-lasting solution | Pipe relining can extend the life of pipes by decades, enhancing water flow and preventing future leaks. |

| Thorough assessments ensure effective repairs | Technicians use specialized tools to evaluate pipe conditions, ensuring targeted and efficient rehabilitation. |

| Eco-friendly alternative to replacement | The technique promotes sustainability by rehabilitating existing pipes without generating excess waste associated with full replacements. |

Defining Pipe Relining: What it Is and Its Purpose

Pipe relining represents an innovative, modern solution for repairing damaged underground pipes without extensive excavation. This advanced technique allows homeowners and property managers to restore pipe functionality while minimizing disruption to landscaping, driveways, and existing infrastructure.

The Fundamental Concept of Pipe Relining

At its core, pipe relining is a trenchless rehabilitation method that involves creating a new, seamless pipe within an existing damaged pipe. The process transforms the interior of deteriorating pipelines by inserting a flexible, resin-coated liner that hardens and forms a robust, corrosion-resistance layer. This technique effectively seals cracks, prevents leaks, and reinforces the structural integrity of underground plumbing systems.

Key advantages of pipe relining include:

- Minimizes landscape disruption

- Reduces overall repair costs

- Provides long-lasting pipe protection

- Eliminates the need for extensive digging

How Pipe Relining Works

The pipe relining procedure follows a precise, scientific approach. Technicians begin with a thorough sewer camera inspection to map the pipe’s condition and identify specific damage areas. After cleaning the pipe using high-pressure hydro jetting, a custom-fitted liner saturated with specialized epoxy resin is inserted into the damaged pipe.

Once positioned, the liner is inflated and heated, causing the resin to cure and bond with the existing pipe walls. This creates a smooth, durable new pipe interior that effectively restores water flow and prevents future structural deterioration. The entire process typically takes several hours and can extend the life of existing pipes by decades, making it a strategic investment for residential and commercial property owners.

This table outlines the main steps of the pipe relining process, providing a clear overview for readers interested in how this modern solution is implemented.

| Step | Description |

|---|---|

| 1. Assessment | Technicians use sewer cameras to inspect and map the condition of the existing pipe. |

| 2. Cleaning | High-pressure hydro jetting clears debris and buildup, ensuring optimal liner adhesion. |

| 3. Measurement | Precise measurements are taken to fabricate a custom liner tailored to the pipe. |

| 4. Liner Installation | A resin-saturated liner is inserted, positioned, and inflated within the damaged pipe. |

| 5. Curing | Controlled heat and pressure initiate resin curing, bonding the liner to the pipe walls. |

| 6. Final Inspection | The relined pipe is examined to confirm seamless restoration and restored flow. |

The Importance of Pipe Relining for Homeowners in the GTA

Pipe relining offers significant advantages for homeowners in the Greater Toronto Area, addressing unique infrastructure challenges that arise from aging residential plumbing systems. By providing a cost-effective and minimally invasive solution, this innovative technique helps preserve property value and prevent extensive damage caused by deteriorating underground pipes.

Environmental and Infrastructure Challenges

The GTA experiences diverse environmental conditions that can rapidly accelerate pipe deterioration. Seasonal temperature fluctuations, clay-heavy soil compositions, and older urban infrastructure create substantial stress on residential plumbing systems. Underground pipes in Toronto neighborhoods frequently face challenges such as root intrusion, ground movement, and gradual material degradation.

Specific challenges include:

- Extreme freeze-thaw cycles causing pipe expansion and contraction

- Clay soil conditions leading to ground shifting

- High water table regions increasing moisture-related pipe damage

- Historical infrastructure with aging material vulnerabilities

Economic and Property Protection Benefits

Pipe relining represents a strategic investment for homeowners seeking to minimize long-term infrastructure expenses . Traditional pipe replacement methods involve extensive excavation, potentially damaging landscaping, driveways, and structural foundations. In contrast, pipe relining preserves property aesthetics while providing robust, long-lasting pipe rehabilitation.

By choosing pipe relining, homeowners can explore comprehensive plumbing solutions that address underground infrastructure challenges without disruptive construction processes. The technique offers a proactive approach to maintaining residential plumbing systems, ultimately protecting property values and preventing costly future repairs.

How Pipe Relining Works: Key Processes Explained

Pipe relining represents a sophisticated engineering approach to rehabilitating underground infrastructure without extensive excavation. This advanced technique transforms damaged pipes through a precise, scientifically designed process that restores functionality and structural integrity with minimal disruption.

Comprehensive Pipe Assessment and Preparation

Before initiating the relining process, technicians conduct a thorough diagnostic evaluation using specialized sewer camera inspection technologies. This critical first step allows professionals to map the exact condition of the underground pipe, identifying specific damage zones, measuring pipe dimensions, and determining the most appropriate rehabilitation strategy.

Preparation stages include:

- High-pressure hydro jetting to remove debris and buildup

- Detailed pipe mapping and damage documentation

- Precise measurements for custom liner fabrication

- Comprehensive structural integrity assessment

Technical Relining Methodology

The pipe relining procedure involves inserting a custom-fabricated flexible liner saturated with specialized epoxy resin into the damaged pipe. This liner is meticulously engineered to match the precise dimensions and configuration of the existing pipe. learn more about our professional plumbing techniques to understand the complexity of this process.

Once positioned, the liner undergoes a transformative curing process. Technicians use controlled heat and pressure to activate the resin, causing it to expand and bond seamlessly with the existing pipe walls. This creates a smooth, durable interior pipe surface that effectively restores water flow, prevents future leaks, and reinforces the pipe’s structural framework. The entire rehabilitation process typically takes several hours, providing a long-lasting solution that can extend pipe functionality by decades.

Materials and Techniques Used in Pipe Relining

Pipe relining leverages advanced materials and sophisticated engineering techniques to transform damaged underground pipes. The selection of specialized materials and precise application methods are crucial in creating durable, long-lasting pipe rehabilitation solutions that withstand diverse environmental conditions.

Advanced Liner Materials

Modern pipe relining depends on high-performance composite materials designed to provide exceptional structural integrity and resistance to corrosion. Technicians utilize specialized liners composed of flexible fabric layers saturated with advanced epoxy resins. These materials are engineered to adapt to existing pipe geometries while creating a seamless, smooth interior surface.

Key characteristics of pipe relining materials include:

- Exceptional chemical resistance

- High tensile strength

- Flexibility to accommodate pipe movement

- Resistance to root intrusion

- Minimal internal friction for improved water flow

Innovative Application Techniques

The pipe relining process employs sophisticated techniques that ensure precise liner installation and optimal bonding. Inversion and pulling methods are commonly used, allowing technicians to position the resin-saturated liner accurately within damaged pipes. explore our comprehensive plumbing rehabilitation strategies to understand the complexity of these advanced techniques.

Specialized curing processes involving controlled heat and pressure transform the flexible liner into a rigid, permanent pipe structure. Technicians meticulously monitor temperature and pressure to ensure complete resin polymerization, creating a robust new pipe interior that effectively seals cracks, prevents leaks, and restores full hydraulic functionality. This innovative approach provides homeowners with a cost-effective, minimally invasive solution for underground pipe rehabilitation.

Long-Term Benefits of Choosing Pipe Relining Over Traditional Methods

Pipe relining represents a transformative approach to underground infrastructure repair, offering substantial advantages over conventional pipe replacement techniques. This innovative method provides homeowners with a comprehensive solution that addresses structural issues while minimizing potential property disruption and long-term maintenance costs.

Economic and Property Preservation Advantages

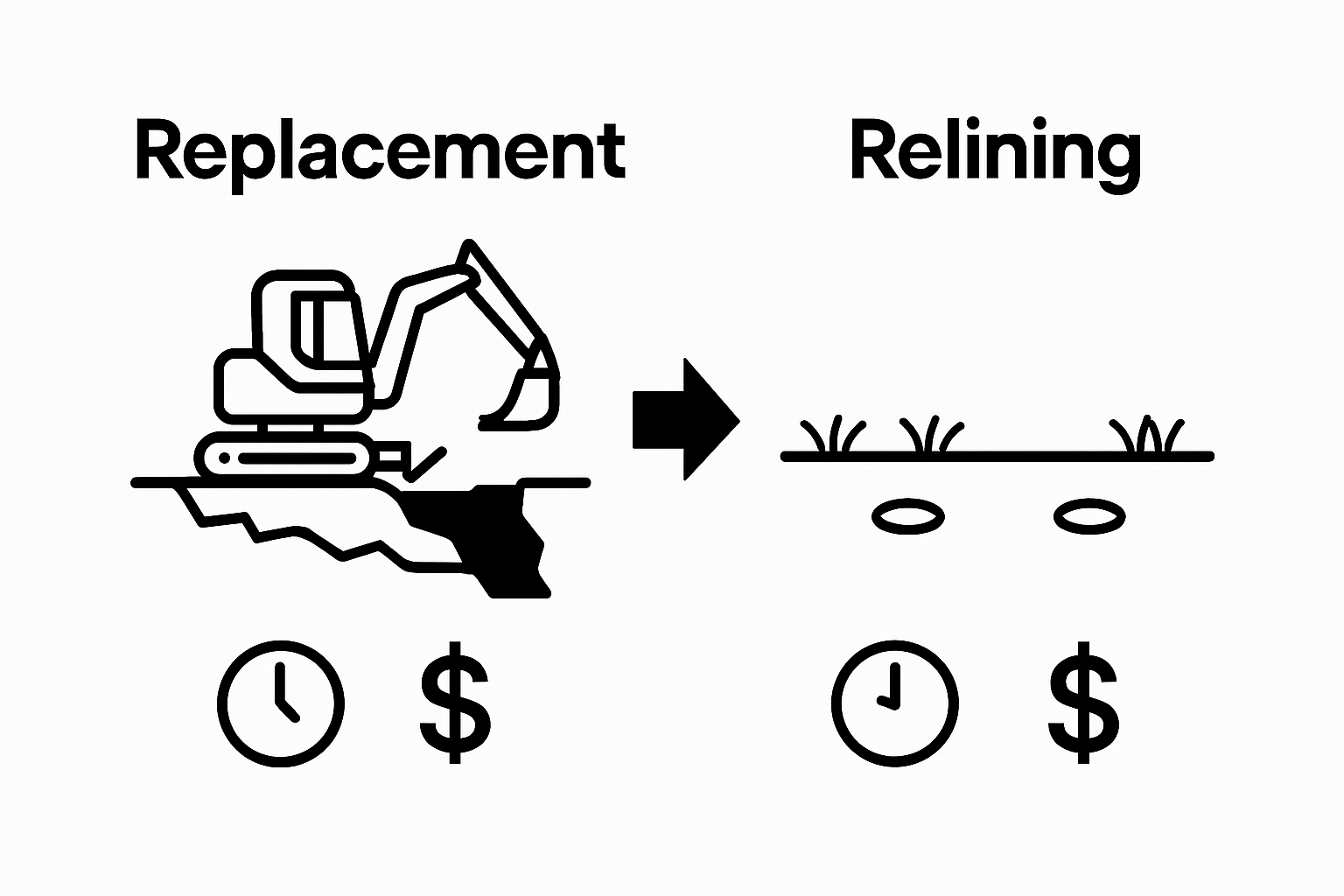

Traditional pipe replacement methods often involve extensive excavation , requiring significant financial investment and causing substantial landscape destruction. Pipe relining eliminates these challenges by creating a new pipe interior without removing the existing infrastructure. Homeowners can avoid costly landscaping restoration, driveway reconstruction, and structural disruptions associated with conventional pipe replacement approaches.

The following table highlights the key differences between pipe relining and traditional pipe replacement methods to help homeowners understand their distinct advantages and drawbacks.

| Feature | Pipe Relining | Traditional Pipe Replacement |

|---|---|---|

| Disruption to Property | Minimal (trenchless, no excavation) | Significant (requires digging up landscaping, driveways) |

| Duration of Repair | Several hours | Multiple days |

| Cost | Lower overall (no extensive restoration required) | Generally higher (includes landscaping and structural repairs) |

| Longevity | Extends pipe life by decades | New pipe lifespan varies by material |

| Environmental Impact | Eco-friendly, less waste | More waste due to removal and disposal of old pipes |

| Suitability | Ideal for most damaged pipes in situ | Necessary for fully collapsed or severely misaligned pipes |

Key economic benefits include:

- Reduced overall repair expenses

- Minimal property landscape disruption

- Faster rehabilitation process

- Lower long-term maintenance requirements

- Preservation of existing landscape and infrastructure

Durability and Performance Improvements

Modern pipe relining techniques create a seamless, corrosion-resistance pipe interior that significantly extends underground infrastructure functionality. The specialized epoxy resin used in relining provides superior structural integrity, effectively preventing future leaks, root intrusions, and material degradation. understand more about strategic home maintenance planning to appreciate the comprehensive benefits of this advanced technique.

The rehabilitated pipe demonstrates enhanced performance characteristics, including improved water flow, reduced friction, and increased resistance to environmental stressors. Homeowners can expect a pipe rehabilitation solution that potentially extends infrastructure lifespan by decades, offering a sustainable and cost-effective alternative to complete pipe replacement.

Need Reliable Pipe Relining in Toronto? Protect Your Home and Your Peace of Mind

Are you worried about disruptive pipe repairs, costly property damage, or recurring drainage problems? The article explained how pipe relining is the smart, no-dig solution to restore and reinforce your aging pipes while preserving your landscape and protecting your investment. At DrainWorks Plumbing, we know that Toronto homeowners face unique challenges like root intrusion, shifting soil, and freeze-thaw cycles. Our experienced, award-winning team combines over 30 years of expertise with advanced trenchless technology to deliver lasting results.

Why wait for a small leak or backup to turn into a bigger headache? Visithttps://drainworks.com to learn how our certified technicians use sewer camera inspections and tailored relining materials for a seamless, stress-free experience. Book your assessment today to enjoy the benefits of modern pipe relining and avoid hidden costs down the road. Your property deserves the best protection now.

Frequently Asked Questions

What is pipe relining and how does it work?

Pipe relining is a trenchless rehabilitation method that involves creating a new, seamless pipe within an existing damaged pipe. The process includes inserting a flexible, resin-coated liner, which hardens to restore functionality and prevent leaks.

What are the advantages of choosing pipe relining over traditional pipe replacement methods?

Pipe relining minimizes disruption to landscaping and existing infrastructure, reduces repair costs, and extends the life of pipes without the need for extensive excavation.

How long does the pipe relining process take?

The entire pipe relining process typically takes several hours to complete, allowing for a quick rehabilitation of underground plumbing systems with minimal downtime.

What kinds of issues can pipe relining address in plumbing systems?

Pipe relining effectively seals cracks, prevents leaks, and reinforces the structural integrity of pipes affected by root intrusion, ground movement, and material degradation.